charpy impact tests dimensions|charpy impact chart : importer The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test . El video “Mortal piscina zacarías original 2009” se originó a partir de un terrible accidente en una piscina. En las imágenes, se puede observar cómo un joven intenta realizar una .

{plog:ftitle_list}

WEBHours Sun 10:00 AM - 7:00 PM Mon 9:00 AM - 8:00 PM

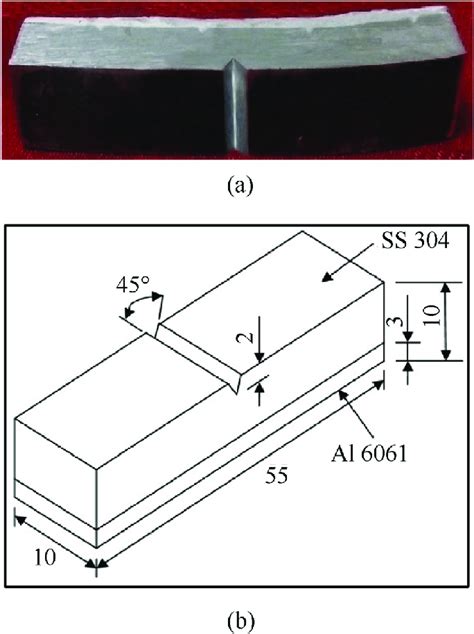

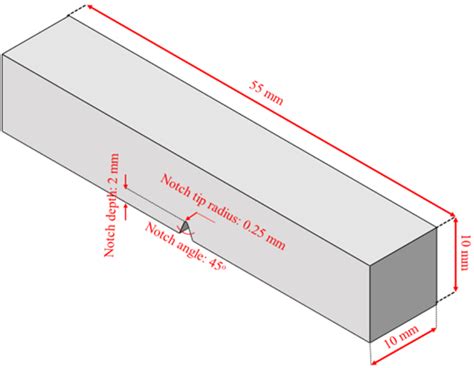

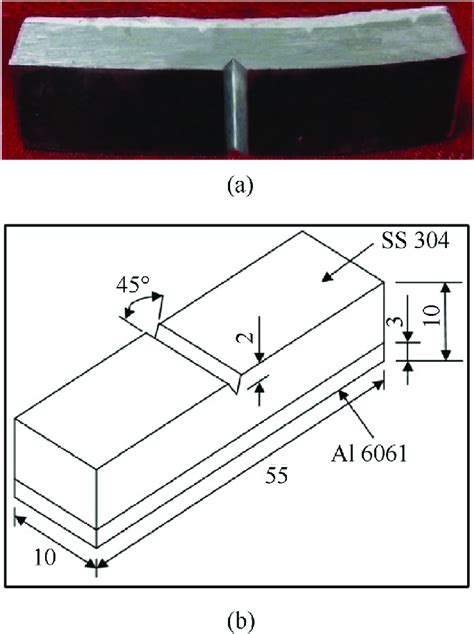

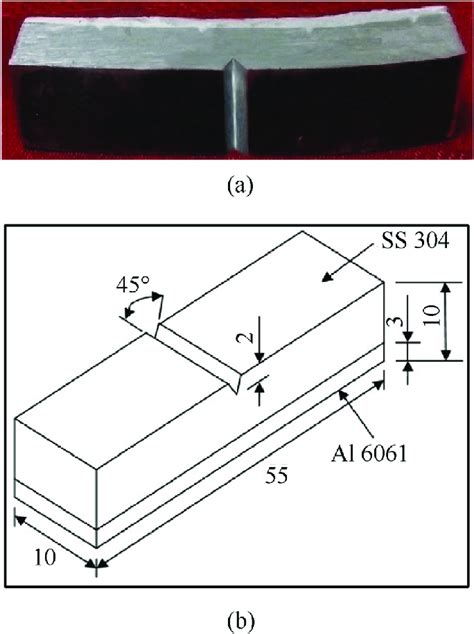

The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy .

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .Length: 55 mm. Width: 10 mm; bar width at notch: 5 mm. Thickness: 10 mm. The u-notch is in the center of the specimen and has a radius of 1 mm. Dimensions for specimens with keyhole notch (Charpy) to ASTM E23.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The test specimens are to be machined to the dimensions and tolerances given in Table 2.3.1 Dimensions and tolerances for Charpy V-notch impact test specimens and are to be carefully .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . Any test specimen preparation, conditioning, dimensions and testing parameters required by the materials specification sha. The store will not work correctly when cookies are disabled. All. All Meetings & Symposia Standardization . Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics D6110-18 ASTM .

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .

The test specimens are to be machined to the dimensions and tolerances given in Table 2.3.1 Dimensions and tolerances for Charpy V -notch impact test specimens and are to be carefully checked . 3.2.2 Charpy V-notch impact tests may be carried out at ambient or lower temperatures in accordance with the specific requirements given in subsequent . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type . Vernier calipers (to measure the dimensions of the specimen) (b)Theory Some materials like cast iron, glass and hard plastics o er considerable resistance to .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them had a .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. AfterThe outer dimensions of specimens to ASTM D256 are specified to a length of 2.5 in (63.5 mm) and a height of 0.5 in (12.5 mm). The width of injection molded specimens may be between 0.118 in (3.0 mm) and 0.5 in (12.5 mm), whereby the use of specimens with a width of 1/8 in (3.2 mm) or 1/4 in (6.35 mm) is common. . A Charpy or Izod impact test .Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of metals. It is a standardised high strain-rate test that can measure the amount of energy absorbed in a material. . The standard Charpy impact specimen with dimensions of 10 mm in depth, 10 mm in width and 55 mm in length and a V-shaped .

dimensions are tuned to the cantilever-beam configuration for Izod testing. Similar to Charpy SRMs, Izod specimens are sold in sets of five . Splett JD, McCowan CN, Iyer H and Wang C Computing Uncertainty for Charpy Impact Machine Test Results NIST-SP 960-18 (2008) Siewert TA Evaluation Specimens for Izod Impact Machines (SRM 2115): Report ofCHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . is to mold, condition and test the specimens using the size, dimensions and test method. The difference between ASTM and ISO will exist as they are of two different specimen .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . A: The Charpy impact test was developed around 1900 and became known as the Charpy test after its inventor, Georges Charpy. It has since become a standard test method for evaluating material toughness. Q: . Charpy impact test. The Charpy test is one of the most common tests for determining impact energy. In this test, the metal sample is placed horizontally and centered between the supports of a pendulum. . The specimen used in the Charpy test has standard dimensions defined by ASTM E23. Typically, the specimen has a length of 55 mm, a width of .Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch . Specimen Position. Horizontally, Notch facing away from the pendulum. Vertically, Notch facing towards the pendulum. . dimensions and test method. The difference between ASTM and ISO will exist as they .

Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) and an experimental part (indirect verification). The direct verification consists in the detailed evaluation of machine dimensions, alignment, and other physical quantities and variables. The indirect verification requires

charpy test sample dimensions

V-notch Charpy impact test has been widely used to qualify toughness of steels and welds (e.g., [5, 6]). In this work, instrumented Charpy tests of pre-charged steel specimens were conducted at ambient temperature using a pendulum machine with a capacity of 750 J. Two to three repetitive specimens were tested for each pre-charging condition.Charpy specimens according ASTM E23-02a were manufactured. Figure 5 shows the dimensions of machined specimens. The toughness impact tests were carried out in a Rosand V1.01 machine (Rosand .

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. This notch, which can be either V-shaped or U-shaped, is placed facing away from the pendulum and helps to concentrate the stress .The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated.Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values obtained can be used for quality control or to differentiate general toughness. Test Procedure:

ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals.This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. In addition to tension tests, the standard also outlines charpy impact, .

A total of 7 specimens for Charpy impact test were obtained by cutting each composite plates according to ASTM D6110 dimensions [28]. The tests were performed in a PANTEC instrumented pendulum, Model XC-50, 1 × 220 V × 60 Hz. Fig. 3 illustrates the prepared specimens for the Charpy tests. Download : Download high-res image (294KB)

thule mac drop test

17 de set. de 2023 · Goat88bet เว็บเดิมพันออนไลน์ ครบวงจร ไม่ว่าจะเป็น สล็อตออนไลน์ คาสิโนสด Goatbet เรามีครบจบที่เดียว สมาชิกใหม่รับเครดิตฟรี 100 ไม่ต้อง .

charpy impact tests dimensions|charpy impact chart